Single Axle Trailers

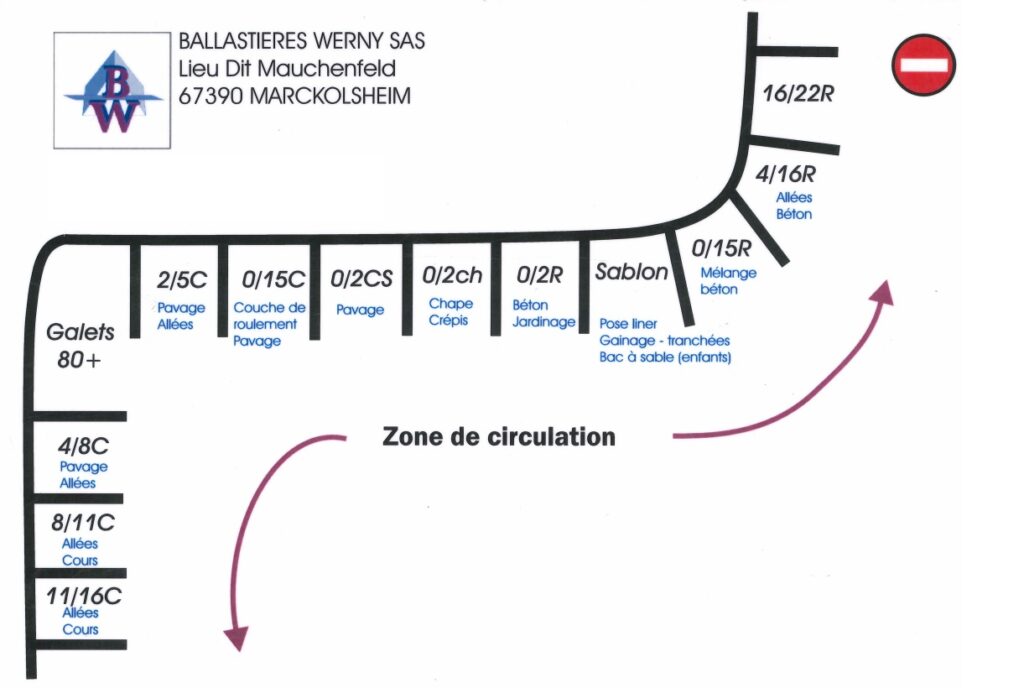

Introduced in 2008, the boxes are away from traffic and dedicated to loading single axle trailers. There is concrete mix, masonry sand, cape/crepi sand, draining roll, crushed driveways or paving, and 0/80 all-comers. Billing is flat.

Process:

Presentation at the office -> Empty passage on the rocker -> Arrow route -> Shovel loading by you – > Back on the rocker.

Double axle trailers

In this case, loading is possible on site and only at the loader. The billing will be by weight.

Process:

Presentation at the office -> Vacuum passage on the rocker -> Loading on site -> Back on the rocker.

! For your safety, it is forbidden to get out of the vehicle!

——————————————————————————————————————————————————————————————————————————–

The concrete mix:

The proportion of the 0/15R mixture is 50% of 0/2R – 50% of 4/16R. The mixture makes it easy to make.

The following requirement will be on a manufacturing basis for 1 M3 of concrete:

- Slab, garage floor, terrace and foundation: 350 KG of cement – 1,850 KG of 0/15R – 175 L of water

- Lintel, beam: 400 KG of cement – 1,750 KG of 0/15R – 200 L of water.

NB: If 0/15R is wet, reduce water dosage.